During the American revolution, in Bermuda and on Cape Cod, windmills were used to pump water for salt making. In Mykonos and on other Greek islands, windmills were used to mill flour and remained in use until the early 20th century.

Wind direction is referred to by the compass direction from which the wind blows; weathervanes are used to show that wind direction and anemometers are used to measure the speed. Harnessing the wind by usimg turbines can provide energy for a multitude of uses.

A 1.5kW turbine can produce nearly 4,000 kilowatt hours (kWh) of electricity per year – the equivalent of almost all of the annual 4,700 kWh used by an average household. A 5kW turbine or larger allows the opportunity of doing even better by selling the surplus unused power back to the Grid.

A wind turbine converts the kinetic energy of wind into mechanical energy. If the mechanical energy is used directly by machinery, such as a pump or grinding stones, the machine is usually called a windmill. If the mechanical energy is then converted to electricity, the machine is called a wind generator.

There are generally two types of wind turbine determined by their direction of travel; horizontal axis and vertical axis. A horizontal axis machine has its blades rotating on an axis parallel to the ground. A vertical axis machine has its blades rotating on an axis perpendicular to the ground. There are a number of available designs for both and each type has certain advantages and disadvantages.

Although vertical axis wind turbines have existed for centuries, they are not as common as the horizontal ones. This is mainly because they do not take advantage of the higher wind speeds at higher levels above ground in the way that horizontal axis turbines can.

Vertical axis wind turbines (VAWTs), are considered to be as efficient as current horizontal axis systems, and might well be more practical, simpler and significantly cheaper to build and maintain than horizontal axis wind turbines (HAWTs). They also have other inherent advantages, such as they are always facing the wind. VAWTs could be crucial in mitigating grid interconnect stability and reliability issues currently facing electricity producers and suppliers.

Vertical axis wind turbines (VAWTs) in addition to being simpler and cheaper to build have the following advantages:

The advantages of Horizontal Axis Wind Turbines (HAWT)

HAWT disadvantages

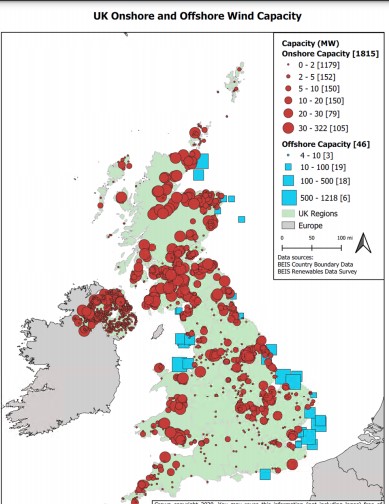

About 40% of Europe’s wind resource is available in the British Isles and Scotland has been declared the windiest country in Europe. This has made this manner of sustainable energy generation a big topic of discussion, however the idea of having large turbines erected often leads to opposition and hostility.

Who has seen the wind?

Neither I nor you:

But when the leaves hang trembling,

The wind is passing through.

Who has seen the wind?

Neither you nor I:

But when the trees bow down their heads,

The wind is passing by……Christina Rossetti

Protesters claim that the noise generated by turbines is one reason why they should not be built, but the more modern small wind turbines produce very little noise and in fact can be quieter than the wind itself. In most cases, you would hear no sound from them if you were around 40 metres away.

The amount of noise generated in a busy office is around 60 decibels which is actually more than what you would experience if you were standing a few hundred metres from a commercial wind farm that would be generating about 40 decibels.

From a cost point of view, electricity generated by wind turbines is broadly competitive with electricity from new clean coal-fired power stations and works out significantly cheaper than power from modern nuclear facilities.

One of the main points raised by their opponents is the high visibility of windfarms together with the possible effects on birds.

A 375ft turbine needs about 1,000 tonnes of reinforced concrete to anchor it into the ground. In addition, opponents point to the carbon debt of creating access paths and service roads created; the energy used to manufacture the turbine and the fuel consumed to transport it to its final destination as being reasons why wind turbines may not be as overall environmentally friendly as supporters believe.

The supply of wind is not consistent but extremely variable. Even though a modern wind turbine will produce electricity for perhaps 80% of the time, the output it achieves depends on how fast the wind is blowing. Over the course of a year, it will only generate a third of what it theoretically could. In the power industry, this is termed the ‘load factor’ and the load factor for a conventional power station is notably better, at 50%.

Wind speed limits turbines in other ways too. Electricity can be generated when the wind reaches a gentle breeze, blowing at 10-12 mph; but in severe gale conditions, turbines have to be shut down for safety reasons.

Rising concerns about climate change, air pollution, energy security and energy access, together with uncertain oil prices in recent years, have generated the need to create alternative, low-carbon technology options such as renewables. Wind power has been a pioneering renewable technology in recent years and according to statistics presented by the World Wind Energy Association (WWEA) the overall capacity of all wind turbines installed worldwide by the end of 2019 reached 650,8 Gigawatt, making it the leading renewable energy technology after hydropower.

From 2020, onshore wind will consistently offer a less expensive source of new electricity than the least-cost fossil fuel alternative in most regions. Wind power will remain a key renewable energy option in the coming decades

An onshore wind turbine with a 2.5 – 3.00 MW is thought to produce 6 million KWh of energy per annum.This amount of power could supply about 1,500 households with electricity as the average household in the UK requires 3700 KWh of electricity per year.

Wind power is growing globally and despite Covid 19 disruptions,wind capacity additions reached 65 GW [ including 5.3 GW offshore ] in 2020 – 8% more than in 2019.

According to the GWEC [ Global Wind Energy Council ] in its 2021 Global Wind Report the top five wind energy countries are

[1] CHINA

Produces – 288.32 GW

Onshore – 278 GW

Offshore – 10 GW

[2] UNITED STATES

Produces – 122.32 GW

Onshore – almost all

[3] GERMANY

Produces – 62.85 GW

Onshore – 55 GW

Offshore – 7.7 GW

[4] INDIA

Produces – 38.65 GW

All Onshore

[5] SPAIN

Produces – 27.24 GW

All onshore

Boats with sails have used wind power for nearly 6,000 years and also wind-driven natural ventilation has been used in buildings since ancient times; the use of the wind to provide mechanical power arrived a bit later. It is thought that perhaps for over two thousand years, grain production and the movement of water has been powered by wind machines of some type. Wind-powered pumps were ubiquitous in the Netherlands, in the arid regions of the American Midwest and the Australian outback to drain land or to provide water for animals and steam engines.

Wind power found new applications in lighting buildings which were remote from centrally generated power as electricity became more available to more people. Today, wind-powered generators sizes vary from tiny plants for battery charging at isolated residences, up to massive offshore wind farms.

There is some uncertainty about its use or intention, but the pictured wind-driven machine is one of the earliest on record from the first century in ‘Roman Egypt.

Other early examples would be the prayer wheels of Tibet and China as well as the irrigation project of Hammurabi, the Babylonian emperor.

The Panemone is the earliest recorded windmill design found and it originated in Persian around 700–900 AD. These Panemone windmills were horizontal with long vertical driveshafts with six to twelve rectangular sails covered in reed matting or cloth. It was first built to pump water, and subsequently modified to grind grain as well, spreading in use across the Middle East, Central Asia and later to China and India. Wind-powered machines may have been known earlier, but there is no clear evidence of windmills prior to the 9th century.

Starting around the 1180s, Vertical windmills were used extensively in Northwestern Europe to grind flour and by 1000 AD, windmills were used to pump seawater for salt-making in China and Sicily.

There is record of wind-powered automata from the mid-8th century including wind-powered statues that “turned with the wind over the domes of the four gates and the palace complex of the Round City of Baghdad”. The Green Dome of the palace was surmounted by the statue of a horseman carrying a lance that was believed to point toward the enemy.

The vertical windmills were mentioned in Don Quixote

From about the 12th century, there are mentions of windmills in Europe. Unlike their counterparts in the Middle East, these were vertical mills and some believe that they were inspired by knowledge of horizontal windmills brought back by the Crusades, whereas others believe that the European ones were a totally separate invention.

By the 14th century the Dutch were using vertical windmills to drain areas of land that were below sea level. In England, the advantages of the new wind power over the water mills was that the freezing of the winter did not affect them.

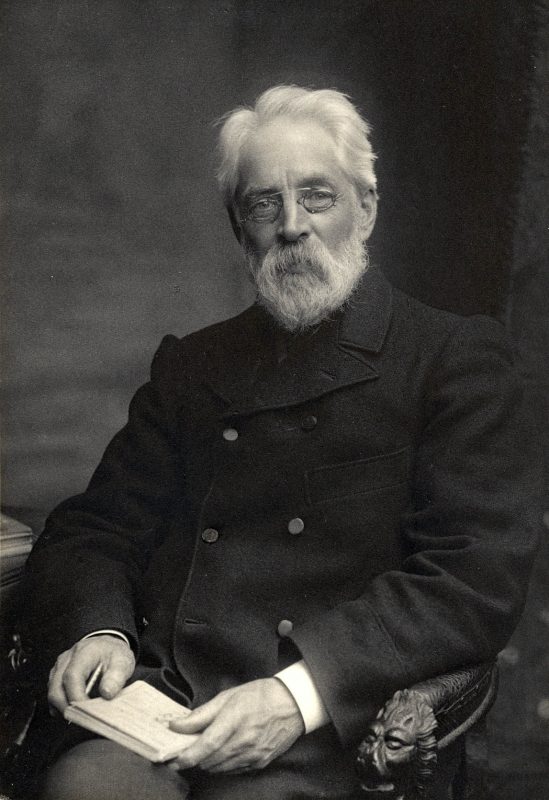

In 1887, the first wind turbine used for producing electricity was built in Scotland by Prof James Blyth

Blyth’s windmill in 1891

The 10m high, cloth-sailed wind turbine was used to charge accumulators developed by the Frenchman Camille Alphonse Faure to power the lighting in Blyth’s cottage in Marykirk, making it the first house in the world to have its electricity supplied by wind power. The professor offered the surplus electricity to the people of the town, but it was turned down on the grounds that electricity was ‘the work of the devil.’

In Cleveland, Ohio in 1887, a larger machine was constructed by the engineering company owned by Charles F. Brush and it operated at his home from 1888 until 1900 when it was abandoned because electricity became available from Cleveland’s central stations. The Brush wind turbine was a 12kW one with a 144 blade rotor of 17 m (56 foot) in diameter and mounted on an 18 m (60 foot) tower. The connected dynamo was used either to charge a bank of batteries or to operate up to 100 incandescent light bulbs, three arc lamps, and various motors in his lab.

In 1891 Danish scientist, Poul la Cour, constructed a wind turbine to generate electricity, which was used to produce hydrogen by electrolysis to be stored for use in experiments and to light the Askov Folk High School. He later solved the problem of producing a steady supply of power by inventing a regulator, the Kratostate, and in 1895 converted his windmill into a prototype electrical power plant that was used to light the village of Askov.In Denmark there were about 2,500 windmills by 1900, used for mechanical loads such as pumps and mills, producing an estimated combined peak power of about 30 MW.

In the American Midwest between 1850 and 1900, perhaps as many as 6 million small windmills were installed on farms to operate irrigation pumps.

1900–1973

Danish development

In Denmark wind power was an important part of a decentralized electrification in the first quarter of the 20th century, partly because of Poul la Cour from his first practical development in 1891 at Askov. By 1908 there were 72 wind-driven electric generators producing from 5 kW to 25 kW. The largest machines were on 24 m (79 ft) towers with four-bladed 23 m (75 ft) diameter rotors. In 1957 Johannes Juul installed a 24 m diameter wind turbine at Gedser, which ran from 1957 until 1967. This was a three-bladed, horizontal-axis, upwind, stall-regulated turbine similar to those now used for commercial wind power development.

Farm power and isolated plants

In 1927 Joe and Marcellus Jacobs opened a factory in Minneapolis to produce wind turbine generators for farm use. These would typically be used for lighting or battery charging, on farms out of reach of central-station electricity and distribution lines. In 30 years the firm produced about 30,000 small wind turbines, some of which ran for many years in remote locations in Africa and on the Richard Evelyn Byrd expedition to Antarctica. Many other manufacturers produced small wind turbine sets for the same market, including companies such as Wincharger, Miller Airlite, Universal Aeroelectric, Paris-Dunn, Airline and Winpower.

In 1931 the Darrieus wind turbine was invented, with its vertical axis providing a different mix of design tradeoffs from the conventional horizontal-axis wind turbine. The vertical orientation accepts wind from any direction with no need for adjustments, and the heavy generator and gearbox equipment can rest on the ground instead of on the top of a tower.

By the 1930s windmills were widely used to generate electricity on farms in the United States where distribution systems had not yet been installed. Used to replenish battery storage banks, these machines typically had generating capacities of a few hundred watts to several kilowatts. Beside providing farm power, they were also used for isolated applications such as electrifying bridge structures to prevent corrosion. In this period, high tensile steel was cheap, and windmills were placed atop prefabricated open steel lattice towers.

The most widely used small wind generator produced for American farms in the 1930s was a two-bladed horizontal-axis machine manufactured by the Wincharger Corporation. It had a peak output of 200 watts. Blade speed was regulated by curved air brakes near the hub that deployed at excessive rotational velocities. These machines were still being manufactured in the United States during the 1980s. In 1936, the U.S. started a rural electrification project that killed the natural market for wind-generated power, since network power distribution provided a farm with more dependable usable energy for a given amount of capital investment.

In Australia, the Dunlite Corporation built hundreds of small wind generators to provide power at isolated postal service stations and farms. These machines were manufactured from 1936 until 1970.

A forerunner of modern horizontal-axis utility-scale wind generators was the WIME D-30 in service in Balaklava, near Yalta, USSR from 1931 until 1942. This was a 100 kW generator on a 30 m (100 ft) tower, connected to the local 6.3 kV distribution system. It had a three-bladed 30 metre rotor on a steel lattice tower. It was reported to have an annual load factor of 32 per cent, not much different from current wind machines.

In 1941 the world’s first megawatt-size wind turbine was connected to the local electrical distribution system on the mountain known as Grandpa’s Knob in Castleton, Vermont, United States. It was designed by Palmer Cosslett Putnam and manufactured by the S. Morgan Smith Company. This 1.25 MW Smith–Putnam turbine operated for 1100 hours before a blade failed at a known weak point, which had not been reinforced due to war-time material shortages.

During the Second World War, small wind generators were used on German U-boats to recharge submarine batteries as a fuel-conserving measure. In 1946 the lighthouse and residences on the island of Neuwerk were partly powered by an 18 kW wind turbine 15 metres in diameter, to economize on diesel fuel. This installation ran for around 20 years before being replaced by a submarine cable to the mainland.

The Station d’Etude de l’Energie du Vent at Nogent-le-Roi in France operated an experimental 800 KVA wind turbine from 1956 to 1966.

1973–2000

US development

From 1974 through the mid-1980s the United States did a great deal to advance the technology and enable large commercial wind turbines. The NASA wind turbines were developed under a program to create a utility-scale wind turbine industry in the U.S. With funding from the National Science Foundation and later the United States Department of Energy (DOE), a total of 13 experimental wind turbines were put into operation, in four major wind turbine designs. This research and development program pioneered many of the multi-megawatt turbine technologies in use today, including: steel tube towers, variable-speed generators, composite blade materials, partial-span pitch control, as well as aerodynamic, structural, and acoustic engineering design capabilities. The large wind turbines developed under this effort set several world records for diameter and power output. The MOD-2 wind turbine cluster of three turbines produced 7.5 megawatts of power in 1981. In 1987, the MOD-5B was the largest single wind turbine operating in the world with a rotor diameter of nearly 100 meters and a rated power of 3.2 megawatts. It demonstrated an availability of 95 percent, an unparalleled level for a new first-unit wind turbine. The MOD-5B had the first large-scale variable speed drive train and a sectioned, two-blade rotor that enabled easy transport of the blades. The 4 megawatt WTS-4 held the world record for power output for over 20 years. Although the later units were sold commercially, none of these two-bladed machines were ever put into mass production. When oil prices declined dramatically from 1980 through the early 1990s, many turbine manufacturers, both large and small, left the business because low oil prices are keeping windmills for electricity generation uneconomical.

Danish development

In 1978 the world’s first multi-megawatt wind turbine was constructed and it pioneered many technologies used in modern wind turbines. Especially important was the novel wing construction using help from German aeronautics specialists. The power plant was capable of delivering 2MW, had a tubular tower, pitch controlled wings and three blades. It was built by the teachers and students of the Tvind school, still runs today and looks almost identical to the newest most modern mills.

Danish commercial wind power development stressed incremental improvements in capacity and efficiency based on extensive serial production of turbines, in contrast with development models requiring extensive steps in unit size based primarily on theoretical extrapolation. A practical consequence is that all commercial wind turbines resemble the Danish model, a lightweight three-blade upwind design.

All major horizontal axis turbines today rotate the same way (clockwise) to present a coherent view. However, early turbines rotated counterclockwise like the old windmills, but a shift occurred from 1978 and on. The blade supplier Økær made the decision to change direction in order to be distinguished from the collective Tvind and their small wind turbines. Some of the blade customers were companies that later evolved into Vestas, Siemens, Enercon and Nordex. Public demand required that all turbines rotate the same way, and the success of these companies made clockwise the new standard.

In the 1970s many people began to desire a self-sufficient lifestyle but because solar cells were too expensive for small-scale electrical generation, some turned to windmills. At the beginning they built ad-hoc designs using wood and automobile parts. Most people discovered that a reliable wind generator is a moderately complex engineering project, well beyond the ability of most amateurs. Some began to search for and rebuild farm wind generators from the 1930s, of which Jacobs Wind Electric Company machines were especially sought after. Hundreds of Jacobs machines were reconditioned and sold during the 1970s.

Following experience with reconditioned 1930s wind turbines, a new generation of American manufacturers such as the Enertech Corporation of Norwich, Vermont started building and selling small wind turbines not only for battery charging but also for interconnection to electricity networks.

In the 1990s, as aesthetics and durability became more important, turbines were placed on top of tubular steel or reinforced concrete towers. Small generators are connected to the tower on the ground, then the tower is raised into position. Larger generators are hoisted into position on top of the tower and there is a ladder or staircase inside the tower to allow technicians to reach and maintain the generator, while protected from the weather.

The start of the 21st century saw cheap fossil fuel but rising concerns over energy security, global warming and fossil fuel depletion leading to more interest in renewable energy. The commercial wind power industry expanded at a rate of about 25% per year, driven by the availability of large wind resources, and rapidly reducing costs owing to improving technology.

Increasing oil prices post 2003 led to increasing fears that peak oil was imminent, which increased interest in commercial wind power. Earlier oil crises had already caused many utility and industrial users of petroleum to move to coal or natural gas and now wind power showed potential for replacing natural gas in electricity generation from the point of view of costs.

Technological developments drove the application of wind power and by 2015, the largest wind turbines were the 8MW capacity Vestas V164 for offshore use. By 2014, over 240,000 commercial-sized wind turbines were producing 4% of the world’s electricity. Total installed capacity exceeded 336GW in 2014 with China, the U.S., Germany, Spain and Italy leading in installations.